Key Applications of Rubber Tape in Electrical Repairs

Electrical Insulation Properties and Performance of Rubber Tape

Understanding dielectric strength and insulation resistance

Rubber tape can handle dielectric strengths ranging from about 15 to 30 kilovolts per millimeter, which means it stops current from flowing between conductors when voltages are below 600 volts. The material also has really high insulation resistance, over 10^12 ohm meters actually, so there's very little unwanted leakage current running through the system. According to research by Peadayesh and colleagues in 2022, this property helps keep electrical systems running efficiently. Because of these characteristics combined, rubber tape remains one of the go to materials for situations where we need to prevent dangerous arcs while still saving on energy costs across various industrial applications.

Preventing electrical leakage in high-voltage and humid environments

In high-humidity environments (exceeding 90%), rubber tape limits leakage current to less than 0.5 mA/m, thanks to its non-polar polymer structure and moisture-resistant additives. Field tests show it prevents flashovers with 94% effectiveness at 10 kV compared to bare conductors. However, for systems above 25 kV, supplemental insulation is recommended.

Comparison with alternative insulating materials

| Property | Rubber Tape | PVC | Silicone |

|---|---|---|---|

| Dielectric strength | 25 kV/mm | 15 kV/mm | 30 kV/mm |

| Flexibility (-40°C) | Maintained | Brittle | Maintained |

| Temperature range | -40°C~90°C | -20°C~80°C | -60°C~200°C |

| Cost per meter | $0.18 | $0.07 | $0.45 |

Silicone offers superior dielectric strength and temperature tolerance, while PVC is more cost-effective but less flexible in cold conditions. Rubber tape balances performance, durability, and cost for general-purpose use.

Is rubber tape sufficient for long-term electrical insulation?

Most rubber tapes still work pretty well after sitting around for five years indoors, retaining about 85% of their original insulating power. But when these materials face repeated temperature swings between +70 degrees Celsius and -30 degrees Celsius, they start breaking down much faster—up to three times quicker actually. For equipment installed outside where sunlight beats down constantly, things get even worse. According to recent updates from NEMA's insulation studies released in 2021, such outdoor setups need new tape replacements roughly every 18 to 24 months. That's a big difference compared to what we see inside buildings, making maintenance planning crucial for facilities managers dealing with both types of installation.

Securing and Insulating Exposed Wires in Real-World Repairs

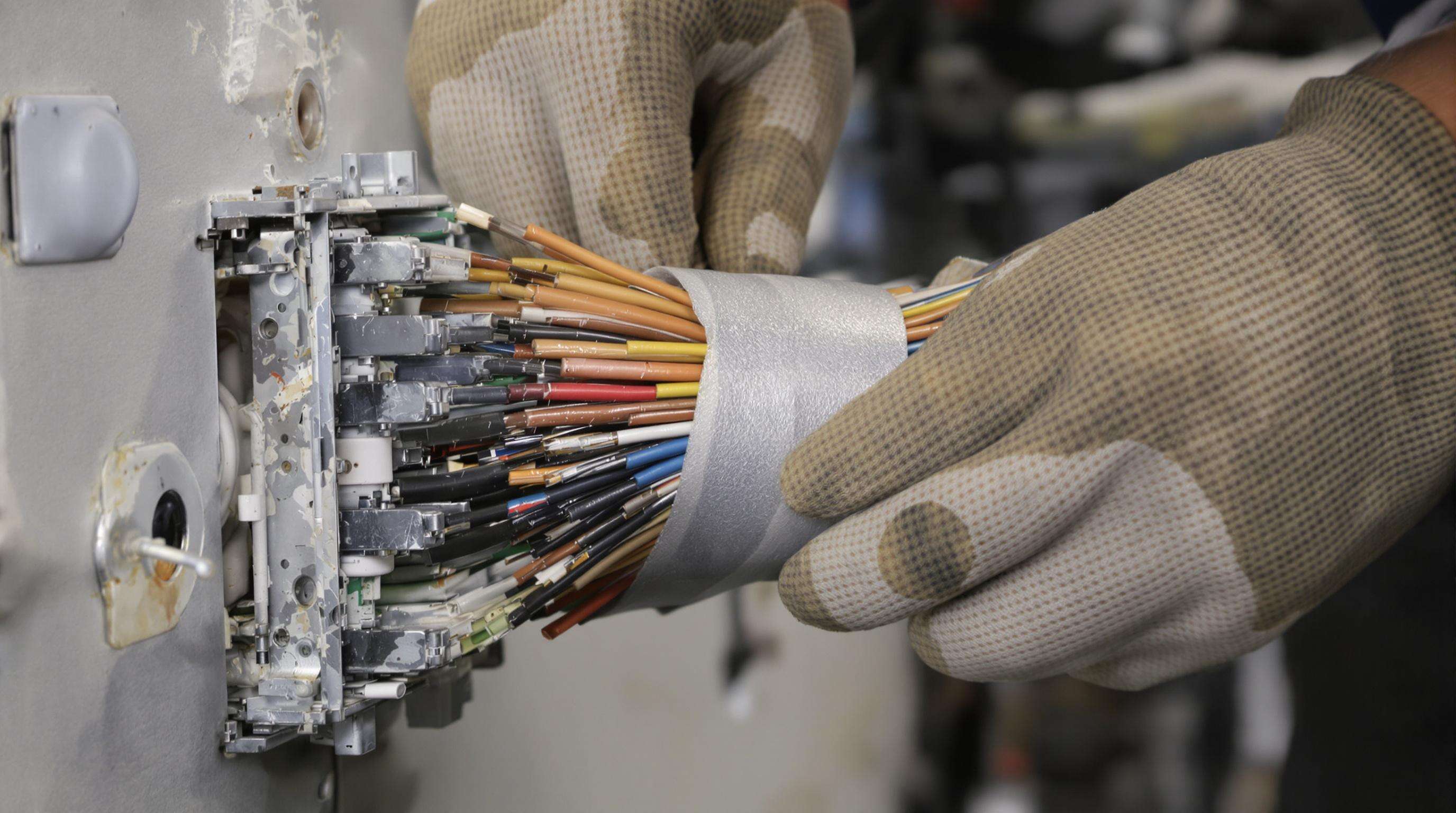

Proper wrapping techniques for exposed conductors

Effective insulation requires 50% overlap and consistent tension (15–20 Newtons). Professionals use spiral wrapping starting 1 inch beyond the damaged area, applying 3–5 layers for circuits under 600V. The 2023 Electrical Safety Foundation International report attributes 23% of field repair failures in commercial settings to improper taping techniques.

Case study: Preventing short circuits in industrial control panels

An automotive plant in the Midwest reduced arc-flash incidents by 41% after adopting reinforced rubber tape protocols on 480V motor terminals. Technicians applied cross-weave wrapping over heat-shrink tubing, addressing insulation wear caused by vibration in robotic assembly lines.

Role of rubber tape in emergency and field repairs

Rubber tape provides reliable temporary protection in urgent situations. Its flexibility at -40°C makes it ideal for cold-weather utility repairs, outperforming vinyl tapes. Linemen use it for 90-second splices, though UL guidelines restrict such applications to 72 hours before permanent repair.

Environmental Resistance: Heat, Moisture, and Durability

Rubber tape’s reliability in electrical systems depends on its resilience to environmental stress. A 2023 materials science study found that premium-grade rubber tapes undergo less than 3% deformation under temperature swings from -40°C to 90°C, making them suitable for HVAC units and solar farm connections.

Performance Under Extreme Temperatures and Thermal Cycling

High-quality rubber tapes maintain elasticity across a temperature range 70% wider than vinyl alternatives. They show no adhesive degradation after repeated thermal cycling (-30°C to 110°C), although surface tackiness decreases by 15% after 500 cycles.

Moisture Barrier Effectiveness in Outdoor and Coastal Installations

After six months of saltwater immersion, rubber tape retains 98% of its moisture resistance, outperforming standard electrical tapes, which retain only 82%. Its closed-cell structure blocks capillary action, a critical advantage in high-humidity coastal and offshore environments such as wind turbine wiring.

Long-Term Durability vs. Real-World Degradation: Resolving the Industry Paradox

While laboratory tests predict a 10-year lifespan, real-world conditions—including combined UV and thermal stress—lead to 23% faster degradation. To address this, UL 510 revisions now require 200-hour weathering simulations. Tapes meeting these updated standards exhibit less than 0.5 mm annual thickness loss.

Adhesion Strength and Mechanical Protection in Demanding Applications

Bond Performance on Copper, Aluminum, and PVC Surfaces

Rubber tape adheres strongly to copper, achieving immediate tack strength up to 2.5 N/cm²—essential for preventing displacement during installation. On aluminum, oxidation necessitates 25% wider overlaps for reliable bonding. When applied over PVC, surface preparation is critical to ensure adhesion, as outlined in industrial adhesive research.

Aging and Long-Term Adhesive Stability (12-Month+ Performance)

According to a recent 2024 study on materials science, high performance rubber tape still holds onto about 92% of its initial stickiness even after sitting through 18 months of extreme temperature changes ranging from minus 40 degrees Celsius all the way up to 90 degrees. That's pretty impressive considering what these tapes go through in real world conditions. The special hydrocarbon plasticized versions are particularly good at stopping the glue from migrating away, which is something that often causes problems in tightly packed wire bundles where space is limited. Looking at actual field reports from various utility projects around the country, there seems to be roughly a three quarters drop in those pesky service call backs whenever technicians switch over to tapes that meet the IEC 60454-3 standards for aging resistance. Makes sense really because nobody wants to keep climbing poles just to fix something that should last longer anyway.

Abrasion and Vibration Resistance in Dynamic Environments

| Factor | Industrial Application | Performance Metric |

|---|---|---|

| Abrasion Resistance | Robotics Wire Harnesses | 200+ cycles @ 15N pressure |

| Vibration Tolerance | Rail Signaling Systems | 0.02mm displacement @ 50Hz |

These properties make rubber tape indispensable in automotive engine compartments and CNC machinery, where constant motion rapidly degrades inferior materials.

Layering Strategies for Enhanced Mechanical Protection

Three-layer wrapping increases cut-through resistance by 300% over single-layer applications. Cross-hatched outer layers deflect abrasion forces, while the middle layer preserves dielectric integrity. This method is widely used in mining equipment and offshore wind turbine repairs, where mechanical and environmental stresses are severe.

Compliance, Certification, and Growing Use in Modern Electrical Systems

Importance of UL and CSA Certification in Professional Repairs

UL-listed or CSA-certified rubber tape is essential for compliance with electrical codes. A 2025 London Daily survey found that 84% of professionals prioritize certified materials, which reduce failure risks by 63% in commercial installations due to verified flame resistance and dielectric stability.

How to Verify Authentic Safety Certifications on Rubber Tape

Authentic certifications include holographic markings and unique QR codes linking to manufacturer verification portals. Serial numbers should be cross-checked against UL’s Online Certification Directory or CSA Group’s database to prevent the use of counterfeit products, which have been linked to 22% of insulation-related incidents.

Rising Adoption in Automotive, Renewable Energy, and Wire Harnessing Systems

The market for certified rubber tape jumped nearly 40% last year as electric vehicles and green energy projects continue their rapid expansion. According to findings from the 2024 Cable Testing Report, rubber tape actually beats traditional heat shrink tubing when it comes to EV battery harness applications. Tests revealed these tapes kept their insulating properties even after going through over 50 thousand temperature changes without failing. Major players in the industry have started adopting this material for critical components too, like connecting parts in solar panel microinverters and inside those massive junction boxes found on wind turbines across the country.

FAQ Section

What is the dielectric strength of rubber tape?

Rubber tape exhibits dielectric strength ranging from 15 to 30 kilovolts per millimeter.

Can rubber tape be used in high-humidity environments?

Yes, rubber tape effectively limits leakage current even in high-humidity environments exceeding 90% humidity.

What are the cost comparisons of rubber tape with other insulating materials?

Rubber tape costs $0.18 per meter, compared to $0.07 for PVC and $0.45 for silicone.

How long does rubber tape last when used outdoors?

Outdoor installations generally require replacement every 18 to 24 months due to environmental factors like UV exposure.

Is rubber tape certified for professional repairs?

UL-listed or CSA-certified rubber tape is essential for compliance with electrical codes in professional repairs.

Recommended Products

Hot News

Hot News

-

Pakistan Business Delegation Visits Our Factory, Seals Partnership With Immediate Deposit

2025-04-29

-

TAPE Team Conquers Shenzhen’s Phoenix Mountain: Unity, Ambition, And New Heights In 2025

2025-02-21

-

The Role of Polyimide Electrical Tape in Electronics Insulation

2025-01-21

-

High Strength Double-sided Tape for Secure Bonding

2025-01-15

-

Durable Foam Tape for High-Performance Applications

2025-01-10

-

High Temperature Resistant Masking Protective Tape for Extreme Conditions

2025-01-01