How to Choose the Right Wire Tape for Home Wiring Projects

Understanding Electrical Wire Tape: Function and Core Materials

What is electrical wire tape used for in home wiring?

Wire tape does more than just cover bare wires it actually insulates those exposed conductors, keeps connections sealed tight, and stops accidental shocks during home wiring jobs. What most people don't realize is how important this tape really is for forming that water resistant shield around wire splices and terminal points. Without it, moisture can sneak in and cause all sorts of problems like short circuits at outlets, switches, and inside those metal junction boxes we all hate dealing with. When applied correctly, the tape works wonders at reducing fire hazards too. It traps heat where it belongs inside the insulation rather than letting it escape and potentially ignite surrounding materials something every electrician knows from experience and what safety manuals have been telling us for decades now.

Insulation properties and dielectric strength of electrical tape

Quality electrical tape must withstand at least 600 volts per millimeter (dielectric strength) while maintaining adhesion across temperatures from -18°C to 80°C. Vinyl-based tapes dominate residential use due to their 175%-200% stretch capacity, which ensures tight wraps around irregular shapes without tearing.

Common materials: PVC vs. rubber vs. mastic tape

- PVC Tape: Budget-friendly option with UV resistance, ideal for indoor wiring (exceeds 300% elongation)

- Rubber Tape: Superior cold-weather performance (-55°C rating) and self-fusing properties for outdoor service entries

- Mastic Tape: Self-amalgamating rubber compound designed for underground or damp locations, requiring a UV-resistant overlayer

Mismatched material selection causes 23% of tape-related failures in DIY installations. Always match tape type to environmental stressors like humidity, temperature extremes, and mechanical abrasion.

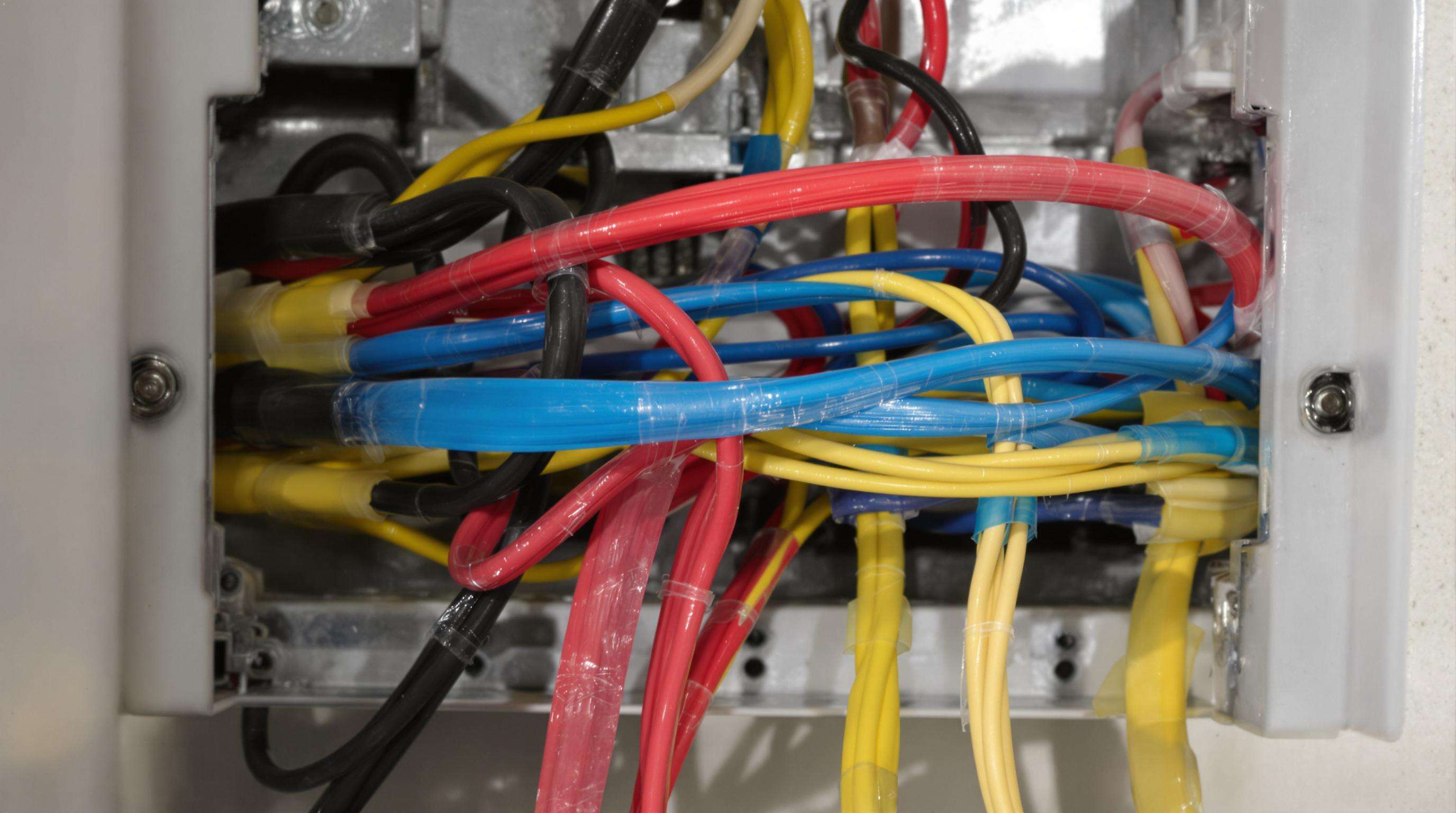

Electrical Tape Color Coding and Safety Compliance

Standard electrical tape color codes for voltage and phase identification

Electrical wire tape color coding creates a universal language for technicians. The industry-standard color codes follow this convention:

| Tape Color | Primary Use | Voltage Range |

|---|---|---|

| Black | General insulation | All voltages |

| Red | Low-voltage circuits | Below 50V |

| Blue | Neutral wires | 120V-600V |

| Yellow | High-voltage phase identification | 480V+ |

Proper color application is critical for phasing tasks (wrapping wire ends to indicate voltage levels). A 2023 Electrical Safety Foundation study found 38% of wiring errors in DIY projects stem from mislabeled voltages.

Residential wire color conventions and safety implications

The National Electrical Code® (NEC) mandates these residential wire colors:

- White/Gray: Neutral conductors

- Green/Bare Copper: Ground wires

- Other Colors: Hot wires (varies by phase)

Matching tape colors to existing wires prevents dangerous contradictions. Using yellow tape (indicating 480V+) on a standard 120V outlet creates unnecessary hazard warnings, confusing future repair technicians.

Risks of misusing black tape and non-standard color practices

Black electrical tape causes 62% of color-coding violations according to International Association of Electrical Inspectors (2023) data. Common risks:

- Camouflaging damaged insulation on hot wires

- Obscuring DIY modifications to existing circuits

- Creating "invisible" junctions that bypass safety switches

Non-compliant practices like using green tape for neutral wires increase shock risks by 5x compared to standard installations (Electrical Safety Authority, 2022). Always verify local codes before modifying industrial-grade color systems in home environments.

Meeting Safety Standards: UL, NEC, and Code-Compliant Tape Selection

Understanding UL, CSA, and NEC requirements for electrical wire tape

When looking at electrical wire tape, certifications from organizations like UL (Underwriters Laboratories), CSA (Canadian Standards Association), and the NEC (National Electrical Code) set important safety standards. UL testing checks how well the tape handles electricity and resists flames, something every electrician knows matters. CSA certification means the product works properly within Canada's electrical requirements. Then there's the NEC, which actually dictates how thick the tape needs to be and what kind of insulation it should have during installation. Before buying any tape, check those certification marks on the packaging. Products without proper certification can be dangerous stuff. Studies show homes using non-compliant tape face nearly double the risk of fire compared to those with certified materials (ESFI 2023). For anyone working on their own wiring projects, getting certified tape isn't just smart, it's basically required if they want to avoid serious problems down the road.

Why code compliance matters in DIY home wiring projects

Skipping electrical code requirements when upgrading homes puts everyone at risk both legally and physically. According to the National Fire Protection Association from 2022, almost half of all DIY electrical fires stem from improper taping techniques where the glue breaks down over time and electricity leaks out. The problems go beyond just catching fire too. Most insurance companies won't cover damage from work that doesn't meet standards, and inspectors will mark these issues during property checks which can really hurt resale value. Choosing the right kind of electrical tape matters a lot for preventing short circuits especially when connecting Romex cables or securing those plastic caps on wires. If folks follow section 110.14 in the National Electrical Code, their wiring should handle normal usage without getting too hot and causing trouble down the road.

Performance of tape grades under high-temperature and load conditions

| Tape Material | Temperature Rating | Voltage Capacity | Key Limitation |

|---|---|---|---|

| PVC | ≈ 80°C (176°F) | ≈ 600V | Brittle at < 0°C |

| Rubber | ≈ 105°C (221°F) | ≈ 1,000V | UV degradation |

| Mastic | ≈ 90°C (194°F) | ≈ 69kV | Difficult removal |

| Certified tapes undergo UL 510 thermal testing, proving stability under residential panel temperatures (typically 65-75°C). Rubber tapes excel in conduit applications with fluctuating loads, maintaining adhesion at 150% stretch. Conversely, budget PVC tapes liquefy above 100°C—dangerous near service entrance connections. Ensure temperature ratings exceed local climate extremes; garages and attics routinely hit 49°C (120°F) in summer months, accelerating adhesive failure in subpar products. |

Proper Application Techniques for Durable and Safe Insulation

Correct installation ensures both effectiveness and long-term safety when using electrical wire tape.

Best practices for applying electrical wire tape securely

Make sure the wire surface is clean and dry first for best results when applying tape. When wrapping, keep some tension on the tape but not so tight that it stretches out of shape or damages the material underneath. A good rule of thumb is to start about an inch or two before where the insulation gets damaged and go past that spot by roughly the same amount. Wrap the tape smoothly in even spirals instead of just slapping it down in overlapping layers. This helps avoid those pesky air bubbles that can weaken the electrical protection properties of the repair job.

Correct tension, overlap, and layering techniques

The best way to stretch electrical tape is around 75% of what it can handle before thinning becomes noticeable. When wrapping wires, keep about half the width overlapping each time. Two full layers usually satisfy most home safety requirements these days. For really important connections though, going with three layers works wonders. Just make sure each new layer goes the opposite direction of the last one so there are no gaps left exposed. The National Electrical Code actually mentions something called Article 110.14 that requires at least 3 mil thickness for stuff that stays put permanently. Getting this right means proper layering techniques matter a lot more than people realize when doing long term wiring jobs.

When to use tape for insulation vs. mechanical protection

Electrical tape works best when used as main insulation for small cuts or scrapes on wires where the actual conductor underneath is still okay. When it comes to protecting against wear and tear or physical hits, regular electrical tape just isn't enough on its own. That's why technicians often pair it with something stronger like split loom covers or bendable plastic tubes. These materials stand up better to constant rubbing that regular tape would simply wear through over time. There is one case worth mentioning though. The thicker mastic tapes rated at 10 mil or more actually offer some decent protection in cramped areas where other options won't fit. Electricians sometimes use these heavier tapes in situations where space limitations make installing proper conduit impossible.

Avoiding over-reliance on tape instead of proper connectors

Never substitute wire tape for dedicated connectors like wire nuts or crimping sleeves. Over-taping compromised terminations creates hazardous "floating" connections. If conductors shift under tape layers, abrasion risks rise by 63% (NFPA 2023 report). Insulate only properly joined wires, using UL 510-rated tape for insulation integrity.

Key Selection Factors: Durability, Environment, and Value

Ease of Use: Stretch, Adhesion, and Tear Resistance

Good electrical wire tape needs to stretch about 25 percent if it's going to form those tight seals around all sorts of odd shaped objects but still stick properly. The better quality tapes actually hold onto wires even when they're covered in grease or dust, thanks to these special cross linked polymer materials that stop the sticky stuff from running out over time which would ruin the insulation. And don't forget about tear resistance either. A good tape should tear cleanly by hand without needing any scissors or knives, which matters a lot when someone is trying to fix something inside a cramped junction box where space is really limited.

Resistance to Moisture, UV, and Chemical Exposure

When installing in outdoor spaces or garages, it's really important to get tapes that can stand up to UV exposure otherwise they'll just crack when exposed to sunlight over time. If dealing with damp areas such as around sump pumps or outside electrical conduits, go for something at least 7 mil thick with those rubber based sticky backs because regular tape just won't hold up against moisture getting through. And don't forget about chemical resistance either. Workshops often have all sorts of stuff floating around like gas, motor oil, and various cleaners that can eat away at normal tapes. So picking ones specifically made to resist these chemicals makes sense if wires are going to be near them regularly.

Balancing Cost and Quality in Consumer Electrical Tapes

Mid-range vinyl tapes (0.5–1.5¢/inch) typically satisfy NEC Article 110.14 insulation requirements for 600V residential systems. Avoid bargain-bin options lacking third-party certification — improperly cured adhesives shrink over time, creating hazardous gaps. High-temp mastic tapes (3–5¢/inch) justify their cost in furnace wiring or attic runs where ambient heat exceeds 90°C (194°F).

FAQs

What is the main purpose of electrical wire tape?

Electrical wire tape is primarily used for insulation, keeping connections sealed tight and preventing accidental shocks in home wiring jobs.

Why are tape color codes important in electrical wiring?

Tape color codes facilitate voltage and phase identification, creating a universal language for technicians to prevent wiring errors.

What are common materials used in electrical tape and their properties?

Common materials include PVC, rubber, and mastic tape. PVC is budget-friendly with UV resistance, rubber tape offers superior cold-weather performance, and mastic tape is designed for damp or underground locations.

How can I ensure the electrical tape I purchase is safe?

Look for certifications like UL, CSA, and NEC on the packaging to ensure the electrical tape meets safety standards.

Can electrical tape be used as a replacement for connectors?

No, electrical tape should not be used as a substitute for dedicated connectors like wire nuts or crimping sleeves.

Recommended Products

Hot News

Hot News

-

Pakistan Business Delegation Visits Our Factory, Seals Partnership With Immediate Deposit

2025-04-29

-

TAPE Team Conquers Shenzhen’s Phoenix Mountain: Unity, Ambition, And New Heights In 2025

2025-02-21

-

The Role of Polyimide Electrical Tape in Electronics Insulation

2025-01-21

-

High Strength Double-sided Tape for Secure Bonding

2025-01-15

-

Durable Foam Tape for High-Performance Applications

2025-01-10

-

High Temperature Resistant Masking Protective Tape for Extreme Conditions

2025-01-01