- Vải chống cháy? Chúng là điều cần thiết cho bất cứ ai quan tâm đến an toàn cháy ở nhà hoặc nơi làm việc.

Hiểu về băng dính chống cháy cho an toàn phòng cháy

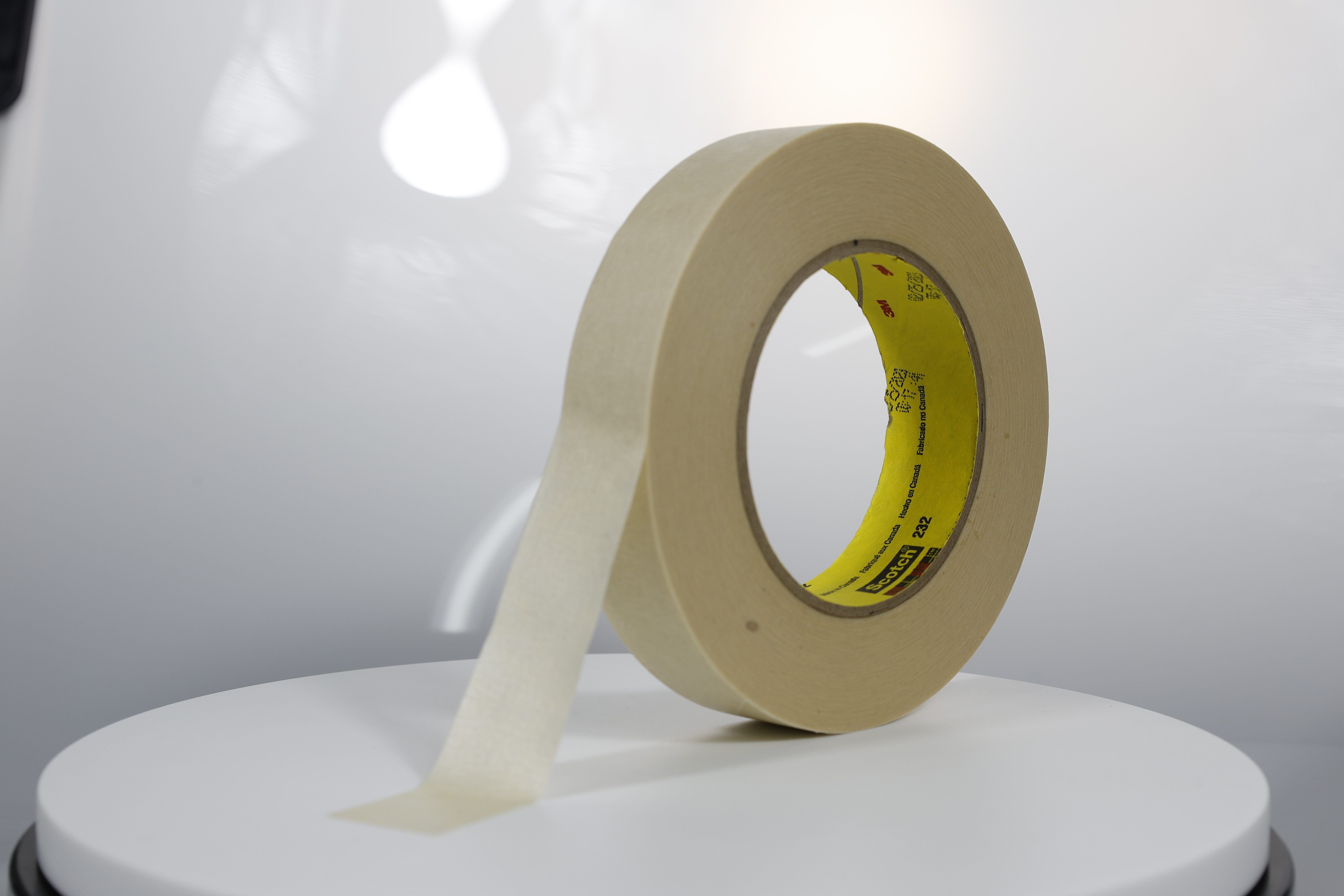

Băng dính chống cháy là loại băng dính chuyên dụng được thiết kế để kháng lại việc bén lửa và ngăn chặn sự lan rộng của ngọn lửa, điều này khiến chúng trở nên quan trọng trong nhiều ứng dụng công nghiệp khác nhau. Những loại băng này được làm từ các vật liệu tiên tiến đáp ứng các tiêu chuẩn an toàn nghiêm ngặt, như tiêu chuẩn UL 94 về khả năng chống cháy, đảm bảo chúng cung cấp sự bảo vệ cần thiết trong các môi trường có nguy cơ cháy nổ cao. Các ngành công nghiệp như xây dựng, ô tô và điện tử rất phụ thuộc vào những loại băng này nhờ khả năng cung cấp sự gia cố cơ học và cách điện.

Hơn nữa, những cuộn băng này đóng vai trò quan trọng trong việc tăng cường các biện pháp an toàn phòng cháy bằng cách bịt kín các khe hở và khớp nối trong các vật liệu dễ cháy. Bằng cách tạo ra một hàng rào chống cháy, băng keo chống cháy giúp ngăn chặn sự leo thang của các vụ cháy, từ đó bảo vệ tính mạng và tài sản. Lớp bảo vệ bổ sung này là không thể thiếu để duy trì độ bền cấu trúc của các tòa nhà và thiết bị trong trường hợp xảy ra tình huống khẩn cấp. Việc thực hiện các biện pháp phòng ngừa như vậy nhấn mạnh tầm quan trọng của băng keo trong các quy trình an toàn phòng cháy toàn diện.

Đặc điểm nổi bật của băng keo chống cháy

Các loại băng keo chống cháy có khả năng chịu lửa cao, đây là đặc điểm quan trọng giúp chúng chịu được nhiệt độ cao mà không bị bén lửa. Khả năng này rất cần thiết trong nhiều ứng dụng công nghiệp, nơi các vật liệu có thể tiếp xúc với nhiệt độ cao. Ngoài ra, những băng keo này còn có tính chất tự dập tắt, nghĩa là chúng sẽ không tiếp tục cháy khi nguồn gây cháy bị loại bỏ. Đặc điểm này giảm đáng kể nguy cơ lan火cháy, cung cấp một lớp bảo vệ bổ sung cho các khu vực nhạy cảm.

Một đặc điểm quan trọng khác của băng keo chống cháy là khả năng dính mạnh mẽ. Những loại băng này được thiết kế để bám chắc chắn ngay cả trong điều kiện khắc nghiệt, ngăn ngừa việc bong tróc trong những thời điểm quan trọng khi cần khả năng chống cháy. Keo dính mạnh đảm bảo băng keo giữ được độ bền và tiếp tục bảo vệ các bề mặt mà nó phủ lên, tăng cường các biện pháp an toàn tổng thể trong các môi trường dễ xảy ra nguy cơ cháy nổ. Điều này khiến chúng không thể thiếu trong các ngành công nghiệp cần giải pháp niêm phong đáng tin cậy để phòng chống các sự cố liên quan đến lửa.

Các vật liệu sử dụng trong băng keo chống cháy

Các loại băng keo chống cháy hiệu quả nhờ vào các công thức hóa học và chất phụ gia cụ thể. Những băng keo này thường sử dụng các vật liệu như hợp chất brom và chất phụ gia gốc phốt pho để tăng cường khả năng chống cháy. Hợp chất brom được đánh giá cao về khả năng ngắt quá trình cháy, trong khi các chất phụ gia gốc phốt pho thường được sử dụng vì khả năng giảm khả năng bắt lửa bằng cách thúc đẩy quá trình hình thành lớp than trên bề mặt. Cả hai loại chất phụ gia này đều đóng vai trò quan trọng trong việc duy trì độ bền của băng keo dưới điều kiện nhiệt độ cao.

Quan trọng ngang bằng là việc lựa chọn keo dán và vật liệu đệm tạo thành nền tảng của băng keo chống cháy. Thông thường, các chất nền này được chọn vì tính ổn định hóa học và khả năng chịu nhiệt độ cao trong khi vẫn giữ được độ bám dính mạnh. Bằng cách đảm bảo rằng các vật liệu đệm và keo dán không góp phần vào quá trình cháy hoặc bị phân hủy dưới áp lực nhiệt, các nhà sản xuất có thể tự tin sử dụng những loại băng keo này trong các môi trường mà an toàn phòng cháy là ưu tiên hàng đầu. Việc lựa chọn kỹ lưỡng các vật liệu này đảm bảo rằng băng keo chống cháy hoạt động đáng tin cậy, cung cấp sự bảo vệ và an ninh trong các ứng dụng quan trọng.

Các ứng dụng đa dạng của băng keo chống cháy

Các loại băng keo chống cháy đóng vai trò quan trọng trong ngành xây dựng, đặc biệt là trong việc niêm phong vật liệu cách nhiệt và giảm thiểu sự lan rộng của火cháy qua tường và trần nhà. Ứng dụng này rất quan trọng trong việc duy trì tính toàn vẹn của các công trình bằng cách ngăn chặn sự xâm nhập của火cháy. Việc sử dụng băng keo chống cháy trong xây dựng đảm bảo rằng các tiêu chuẩn an toàn được đáp ứng, từ đó bảo vệ các tòa nhà khỏi các mối nguy hiểm về火cháy tiềm tàng. Những cuộn băng này cung cấp các khớp kín khí, góp phần vào hiệu quả năng lượng tổng thể và độ an toàn của công trình.

Trong lĩnh vực ô tô, các loại băng keo chống cháy không thể thiếu để bảo vệ dây điện xe và đảm bảo tuân thủ các quy định an toàn. Khi kết hợp với băng dính điện tử chống cháy, những cuộn băng này cung cấp một lớp bảo vệ bổ sung, phòng ngừa rủi ro của các vụ火cháy điện. Sự sử dụng của chúng trong các ứng dụng ô tô nhấn mạnh tầm quan trọng của các chất kết dính chống cháy trong việc đảm bảo an toàn phương tiện và tuân thủ các quy định của ngành.

Hơn nữa, các loại băng keo chống cháy được sử dụng rộng rãi trong hệ thống điện và HVAC, nơi chúng cung cấp cách điện và bảo vệ nhiệt thiết yếu. Trong các môi trường như hệ thống giao thông công cộng, tàu hỏa và sân bay, việc giảm thiểu rủi ro cháy nổ là vô cùng quan trọng. Băng keo chống cháy đóng vai trò lớn trong việc đảm bảo an toàn công cộng bằng cách ngăn ngừa cháy nổ điện và duy trì tính toàn vẹn cấu trúc của các dịch vụ thiết yếu. Sự đa dạng và vai trò quan trọng của những loại băng này nhấn mạnh giá trị của chúng trong các ứng dụng liên quan đến an toàn ở nhiều ngành công nghiệp khác nhau.

Tuân thủ các tiêu chuẩn an toàn

Các loại băng keo chống cháy phải đáp ứng các tiêu chuẩn an toàn nghiêm ngặt để đảm bảo hiệu quả trong việc phòng cháy. Các tiêu chuẩn quan trọng như UL 94 và ASTM E84 nêu rõ các phương pháp thử nghiệm và tiêu chí hiệu suất quan trọng. Ví dụ, UL 94 đánh giá các đặc tính dễ cháy của vật liệu nhựa, cung cấp các phân loại như V0, V1 hoặc V2 dựa trên khả năng kháng lửa. Ngược lại, ASTM E84 đo lường sự lan truyền ngọn lửa và mức độ phát triển khói của vật liệu xây dựng. Hiểu rõ những tiêu chuẩn này là rất quan trọng vì chúng quy định các quy trình an toàn mà các băng keo chống cháy phải tuân theo.

Chứng nhận đóng vai trò quan trọng trong việc tích hợp băng keo chống cháy vào các ngành công nghiệp. Nó cho thấy rằng những băng keo này tuân thủ tất cả các quy định an toàn cần thiết, mang lại sự tin tưởng cho người dùng cuối về thiết kế an toàn phòng cháy của họ. Nếu không có chứng nhận phù hợp, băng keo chống cháy có thể không đạt được các phê duyệt cần thiết, có khả năng làm compromising an toàn. Do đó, việc đạt được chứng nhận không chỉ khẳng định cam kết của nhà sản xuất đối với chất lượng mà còn đảm bảo cho khách hàng về độ tin cậy và tuân thủ các tiêu chuẩn an toàn nghiêm ngặt của băng keo.

Lựa chọn Băng Keo Chống Cháy Phù Hợp

Khi chọn băng keo chống cháy phù hợp, cần xem xét nhiều yếu tố để đảm bảo hiệu suất tối ưu. Trước hết, các yêu cầu cụ thể của ứng dụng, như dải nhiệt độ, môi trường và khả năng tương thích bề mặt, đóng vai trò quan trọng. Ví dụ, một cuộn băng được sử dụng trong môi trường nhiệt độ cao phải có khả năng chịu được những điều kiện đó mà không mất đi tính bám dính. Ngoài ra, việc xem xét môi trường, chẳng hạn như băng có bị tiếp xúc với độ ẩm, ánh sáng UV hoặc hóa chất hay không, cũng rất quan trọng vì những yếu tố này có thể ảnh hưởng đến độ bền và hiệu suất của băng.

Tránh các sai lầm phổ biến là điều quan trọng để đảm bảo hiệu quả của băng keo chống cháy. Một sai sót thường gặp là chọn các loại băng không tuân thủ các tiêu chuẩn an toàn phù hợp, chẳng hạn như UL94 hoặc các chứng nhận cụ thể khác của ngành công nghiệp. Ngoài ra, không xem xét đầy đủ các điều kiện môi trường mà băng keo sẽ được áp dụng có thể dẫn đến các vấn đề về hiệu suất hoặc nguy cơ an toàn. Do đó, việc đánh giá kỹ lưỡng các thông số kỹ thuật của băng keo và đảm bảo nó phù hợp với điều kiện hoạt động là rất quan trọng để đảm bảo cả an toàn và hiệu quả.

Kết luận: Vai trò then chốt của băng keo chống cháy trong việc nâng cao độ an toàn

Tương lai của các loại băng keo chống cháy nằm ở những tiến bộ liên tục trong vật liệu và công thức, điều này sẽ nâng cao hiệu quả và tính đa dụng của chúng. Những đổi mới trong thành phần hóa học và công nghệ keo dán dự kiến sẽ dẫn đến việc sản xuất các loại băng keo có khả năng chống cháy, độ bền và tính an toàn môi trường được cải thiện. Những phát triển này sẽ đáp ứng nhu cầu mới nổi trong nhiều lĩnh vực khác nhau, đảm bảo rằng băng keo chống cháy tiếp tục đóng vai trò quan trọng trong các quy trình an toàn hiện đại.

Việc tích hợp các giải pháp băng keo chống cháy vào tiêu chuẩn an toàn phòng cháy là điều thiết yếu để bảo vệ tính mạng và tài sản. Khi các ngành công nghiệp nỗ lực tuân thủ các quy định an toàn nghiêm ngặt, băng keo chống cháy cung cấp một biện pháp đáng tin cậy, chủ động chống lại rủi ro cháy nổ. Vai trò của chúng trong việc đảm bảo an toàn ở những môi trường quan trọng nhấn mạnh sự cần thiết phải áp dụng băng keo này như một phần không thể thiếu trong chiến lược phòng cháy lâu dài. Bằng cách tăng cường bảo vệ cấu trúc và giảm thiểu nguy cơ cháy nổ, băng keo chống cháy đóng vai trò quan trọng trong các giải pháp an toàn phòng cháy toàn diện.

Recommended Products

Hot News

Hot News

-

Phái đoàn Thương mại Pakistan thăm nhà máy của chúng tôi, ký kết hợp tác với khoản đặt cọc ngay lập tức

2025-04-29

-

Đội TAPE chinh phục núi Phoenix của Thâm Quyến: Thống nhất, tham vọng và những đỉnh cao mới vào năm 2025

2025-02-21

-

Vai trò của băng dính điện polyimide trong cách điện điện tử

2025-01-21

-

Băng dính hai mặt có độ bền cao cho liên kết an toàn

2025-01-15

-

Băng dính foam bền cho các ứng dụng hiệu suất cao

2025-01-10

-

Băng dính bảo vệ che chắn chịu nhiệt độ cao cho các điều kiện khắc nghiệt

2025-01-01