フェンスの塗装ですか?耐久性のあるマスキングテープを使用すれば、きれいできれいな塗装作業が長持ちします。

フェンス用マスキングテープの耐久性における主要因

粘着強度の要件

マスキングテープの粘着強度は屋外用途において重要な検討事項であり、テープが正しく接着し、環境要因に対して信頼性のあるシールを提供することを確保します。屋外での使用において効果的な耐久性を発揮するため、高品質なマスキングテープは通常、少なくとも25オンス/インチの剥離接着強度の基準を満たしています。この仕様は、環境によるストレスに耐えるために不可欠です。さらに、ASTM D3330などの試験方法は、接着性能についての事実に基づいた評価とサポートを提供し、さまざまな条件下でテープがその付着力を維持することを保証します。

紫外線および天候に対する耐性

屋外でマスキングテープを使用する場合、紫外線耐性が重要です。紫外線に長時間さらされることにより、接着力が低下することがあります。また、雨や風、極端な温度変化などの気象条件に耐えることができることも、長期的な接着性を維持するために不可欠です。ASTM D4329の紫外線試験基準に適合したテープは、耐久性が大幅に向上することが研究で示されており、フェンスやその他の外部表面保護に最適です。

素材の構成が重要

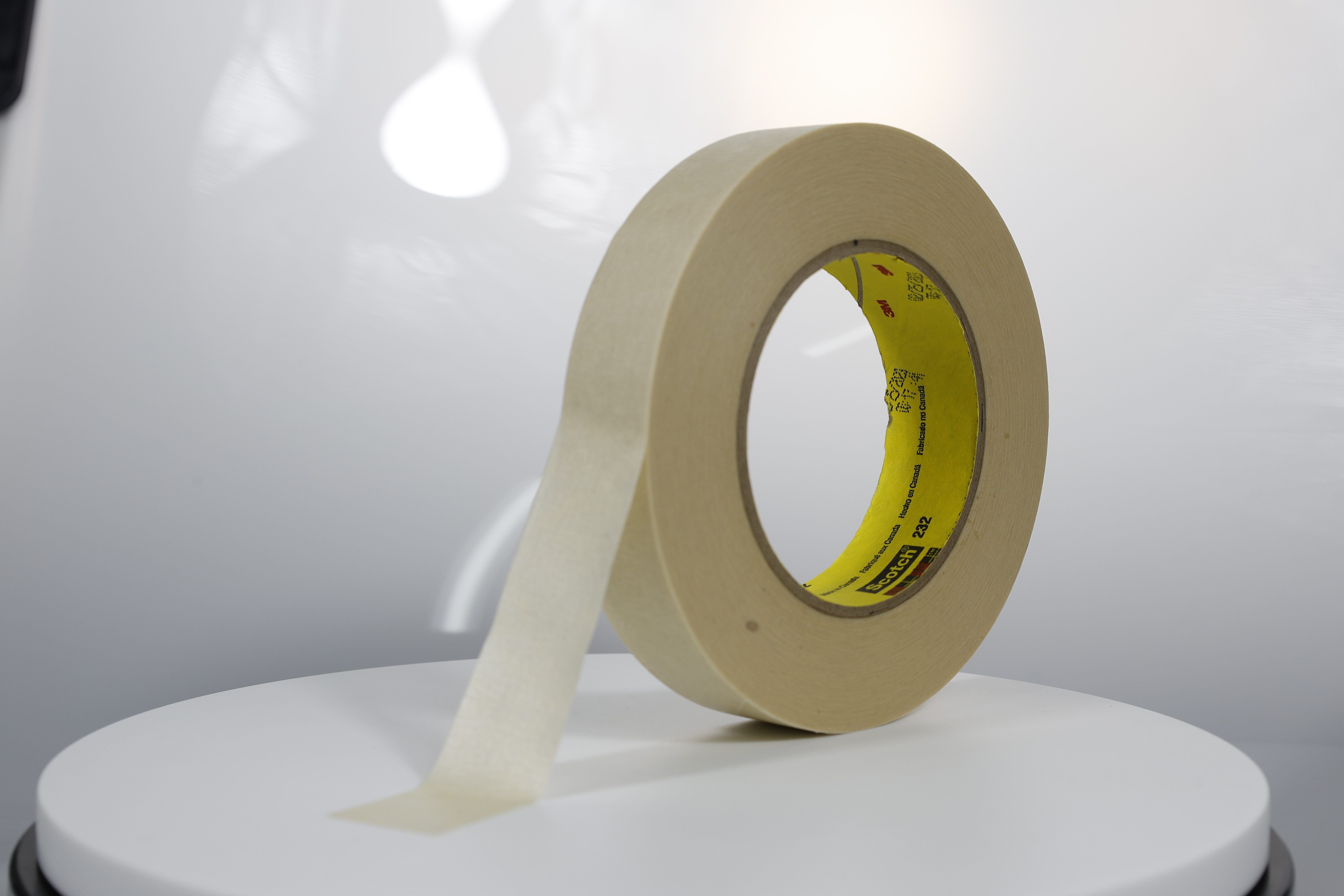

マスキングテープの構成、特にその基材は、屋外環境での耐久性や効率に大きく影響します。ポリエチレンやビニル系のテープは、従来の紙ベースの製品と比較して湿気に対する耐性が高い傾向があります。高品質な基材を使用することで、テープ自体が持つ特性を大幅に向上させ、強度や機能性を高めることができることが研究から示されています。このような素材構成への注目により、性能を維持しながら屋外使用に耐えうるテープを選択することが可能になります。

屋外フェンスに適したマスキングテープの種類

高粘着力ペイントersテープ

過酷な屋外用途には、高密着性のペイント用テープが優れた選択肢です。その優れた粘着力と耐久性により、この種のテープはさまざまな表面にしっかりと接着でき、最大14日間その性能を維持するため、長期にわたる屋外の作業に最適です。多くの専門家は、ペイント用テープがシャープなラインを作り出し、表面を損なうことなくきれいにはがせることを評価しています。その高い性能により、仕上がりがプロフェッショナルなものになるだけでなく、天候にも耐えることができます。

オールウェザーシーリングテープオプション

全天候型シーリングテープは、湿気や極端な温度に耐えるように作られているため、屋外のフェンスに最適で、多用途かつ信頼性の高い使用が可能です。これらのテープには通常、ゴム系接着剤が使用されており、さまざまな環境条件下でも付着性と耐久性を高めます。研究によると、全天候型シーリングテープを選ぶことで、水の浸透リスクを大幅に低下させ、プロジェクトの長寿命化を図ることが可能になります。このため、過酷な天候条件下でも屋外プロジェクトの健全性を維持したい場合に、好ましい選択肢となります。

自動車用マスキングソリューション

屋外フェンス用途には、極端な気象条件に耐えるように設計された自動車用マスキングテープを検討してください。これらのテープは優れた強度と伸縮性で知られており、温度変化によるストレスに効果的に対処できます。業界の専門家は、耐久性および塗料かすみ防止性に優れていることから、屋外プロジェクトに於けるクリーンな仕上げを実現するために自動車用マスキング製品をお勧めします。頑丈な構造により、これらのテープは汎用性があるだけでなく、屋外の過酷な環境から表面を保護する能力があります。

フェンス施工における環境上の課題

日光への暴露と温度の極端な変化

屋外のフェンスに使用するマスキングテープの効果には、日光の影響が大きく関係します。長時間の日光にさらされることでテープ素材が劣化し、接着性が失われ、最終的にテープが早期に機能を停止する原因となることがあります。さらに、極端な温度条件はこれらの問題を悪化させる要因となり、寒冷時ではテープがもろくなり、高温下ではテープが柔らかくなりすぎることで、屋外環境での性能が損なわれます。熱変化試験の研究から明らかになったように、こうした過酷な環境要因は屋外用テープの寿命を大幅に短くするため、このような条件に耐えるように設計されたテープの選定が必要です。

湿気および湿度に関する考慮事項

雨や霧、その他の環境要因による湿気は、フェンス用テープ施工において別の課題を引き起こします。これはマスキングテープの粘着性を低下させ、早期に剥がれたり効果が減少したりする原因になります。さらに高湿度状態ではカビや微生物が繁殖しやすくなり、テープ自体だけでなく、テープが貼られている下地構造にも悪影響を及ぼします。材料科学の研究によりますと、テープ設計に耐湿バリア機能を取り入れることで、耐久性と粘着品質を大幅に向上させることが示されており、このような湿潤条件に対応できるテープ選びの重要性が強調されています。

テープ選定および使用における一般的な間違い

表面処理の重要性を見逃すこと

テープを貼る際に最も一般的な間違いの1つは、表面処理が不十分であることにより、密着不良を起こすことが多いです。テープを効果的に接着させるためには、表面をしっかりと清掃することが重要です。ほこりや油分、湿気などの汚れはテープの性能に大きな悪影響を与え、その効果や寿命を縮めてしまう可能性があります。接着技術に基づく知見によれば、適切に清掃を行うことでテープの寿命をほぼ倍にすることができます。したがって、表面を正しく準備する時間を確保することで、長期的に良い結果を得ることができ、不要な費用や修理を避けることが可能になります。

テープ剥離のタイミングを無視すること

よくある間違いの一つは、テープ剥離に推奨される時間枠を無視することです。これにより、接着剤の残渣や、場合によっては表面自体の損傷を引き起こす可能性があります。各タイプのテープには特定の剥離タイミングがあり、クリーンな仕上がりを保つために遵守する必要があります。テープ使用に関する研究では、テープ剥離の適切なタイミングが高額な修復作業を防ぐために重要であることが示されています。これらのガイドラインを注意深く守ることで、テープ自体と下地の表面の寿命を延ばし、プロフェッショナルで清潔な外観を維持することが可能になります。

屋内用テープの屋外使用

インテリア用のテープを屋外用途に使用することは大きな間違いです。これらのテープは、過酷な環境条件に耐えるための耐久性や抵抗性が一般的に不足しています。このような見落としが原因で、紫外線や湿気などの外的要因にさらされた際にテープが剥がれたり劣化したりするケースが多くなります。インテリア用とエクステリア用のテープの違いを理解することは、適切な製品を選ぶために不可欠です。業界の専門家はよく指摘しますが、この一般的な間違いにより作業工数やコストが増加する可能性があります。長期的に見て時間と費用を節約するためには、耐候性に優れたエクステリア用テープへの投資が重要です。

長持ちさせるための最良の実践方法

正しい適用技術

テープを正しく貼ることは、長持ちする結果を得るために重要です。重要な方法の一つは、均等な圧力をかけながらテープを貼ることです。これにより接着性が向上し、空気袋ができる可能性を減らします。この簡単なステップにより、テープの性能を大幅に高めることができます。また、貼り付ける際の最適な温度や表面状態について、製造元のガイドラインに従うことも重要です。これらの推奨事項を無視すると、期待通りの結果が得られず、テープの剥がれやすくなる可能性があります。専門家は常に、時間をかけて正しくテープを貼ることを推奨しています。これは最大限の接着性と耐久性を得るために不可欠な作業です。

適切なタイミングでの除去戦略

テープの除去は、正しく貼ることと同様に重要です。テープの仕様に応じて除去工程を計画することで、耐久性を高め、表面の状態を良好に維持できます。除去時に柔らかな方法と適切な工具を使用し、基材を損傷するリスクを最小限に抑えることが推奨されます。また、接着剤の残留を防ぐため、タイミングよく除去することがベストプラクティスとして知られています。これによりプロジェクトの品質を保つだけでなく、清掃や修理にかかる時間やコストを節約することも可能です。適切な除去技術を用いることで、テープ本来の役割を果たさせつつ、後工程への影響を防ぐことができます。

Recommended Products

Hot News

Hot News

-

パキスタンビジネス団体が我が工場を訪問し、即時デポジットでパートナーシップを締結

2025-04-29

-

TAPEチームは深?? のフェニックス山を征服 2025年に統一,野心,そして新たな高み

2025-02-21

-

電子機器絶縁におけるポリイミド電気テープの役割

2025-01-21

-

確実な接着のための高強度両面テープ

2025-01-15

-

高性能アプリケーション向けの耐久性のあるフォームテープ

2025-01-10

-

極限条件に対応した高温耐性マスキング保護テープ

2025-01-01