Wiring up your outdoor lights? Make sure to use UV - resistant electrical tape for long - lasting results.

Understanding UV-Resistant Electrical Tape

UV-resistant electrical tape is specifically designed to withstand the harmful effects of ultraviolet rays, making it an essential product for outdoor applications. This type of tape is typically manufactured using durable materials such as vinyl or rubber, which provide excellent resistance to sunlight exposure. Vinyl, known for its abrasion-resistant characteristics, is commonly used due to its flexibility and long-lasting performance. Rubber, on the other hand, adds water resistance and insulation capabilities, enhancing the tape's overall effectiveness.

The unique properties of UV-resistant electrical tape make it indispensable in settings where sunlight can be a concern. It is particularly useful for outdoor electrical connections, where prolonged exposure to the sun might otherwise degrade standard tapes. Common applications include sealing outdoor wiring, repairing garden lighting systems, and insulating solar panel connections. Its ability to resist moisture and maintain adhesion under intense sun exposure ensures secure and long-lasting protection for your electrical installations.

Best UV-Resistant Electrical Tape for Outdoor Lights

Using UV-resistant electrical tape for outdoor lights is crucial in maintaining the integrity and safety of outdoor wiring. Sunlight can severely degrade non-UV resistant tapes, weakening their adhesive properties and potentially leading to failures. Studies show that non-UV resistant tapes have a higher failure rate in outdoor applications, with up to 30% degrading within a year. In contrast, UV-resistant tapes ensure long-term reliability by preventing such risks, making them essential for outdoor electrical installations.

When selecting a UV-resistant tape, several key features should be considered to ensure optimal performance. First, look for a tape with a suitable thickness as thicker tapes generally offer better insulation and protection. Adhesive strength is another critical feature; the tape should maintain its grip under varying weather conditions. Heat resistance is particularly important since outdoor tapes will be exposed to direct sunlight. Finally, ease of application is vital; opt for a tape that offers flexibility and can stretch to accommodate irregular surfaces. These features collectively contribute to a durable and secure installation for any outdoor lighting setup.

Applications of UV-Resistant Electrical Tape

UV-resistant electrical tape has several practical applications, particularly in outdoor lighting systems. Key uses include securing connections in landscape lighting setups, solar panel installations, and architectural outdoor lighting. These environments demand robust solutions to withstand extended exposure to sunlight and varying weather conditions. The tape's UV resistance ensures it remains effective over time without degrading, thus maintaining the integrity and safety of the wiring in these outdoor settings.

Using UV-resistant electrical tape is crucial for creating weather-resistant wiring solutions. Regular electrical tapes often fail under constant exposure to sunlight and weather extremes, leading to significant hazards such as electrical shorts and potential fires. For instance, in coastal regions where salt air can exacerbate corrosion, UV-resistant tape provides a durable barrier against environmental stressors. This makes it an essential component not only for the longevity of outdoor electrical systems but also for the prevention of risks associated with poor weatherproofing, ensuring continued functionality and safety.

Comparison of UV-Resistant Electrical Tapes

When considering UV-resistant electrical tapes, two prominent types are vinyl and rubber tapes. Vinyl electrical tapes are known for their durability and flexibility. They typically have strong UV resistance due to their abrasion-resistant PVC backing, making them a popular choice for various electrical insulation tasks. Their tensile strength and ability to withstand high temperatures also contribute to their wide usage. In contrast, rubber tapes excel in water resistance and are often utilized in high-voltage applications due to their superior insulating properties. These tapes are non-adhesive and rely on elastic tension to adhere, making them ideal for splicing and terminating cables up to 69 kilovolts.

Evaluating different brands of UV-resistant electrical tape involves examining their reputation, user reviews, and certifications. Brands like Scotch and TradeGear offer high-quality tapes, each with specific certifications such as UL listing and CSA approval that indicate reliability and durability. Scotch’s Super33 Vinyl Electrical Tape, for instance, is highly acclaimed for its superior performance in extreme temperatures, UV resistance, and versatility, as indicated by user reviews and its high voltage rating. In essence, selecting the best tape depends on the specific requirements of the application and the environmental conditions it will face.

LSI Terms: Types of Electrical Tapes

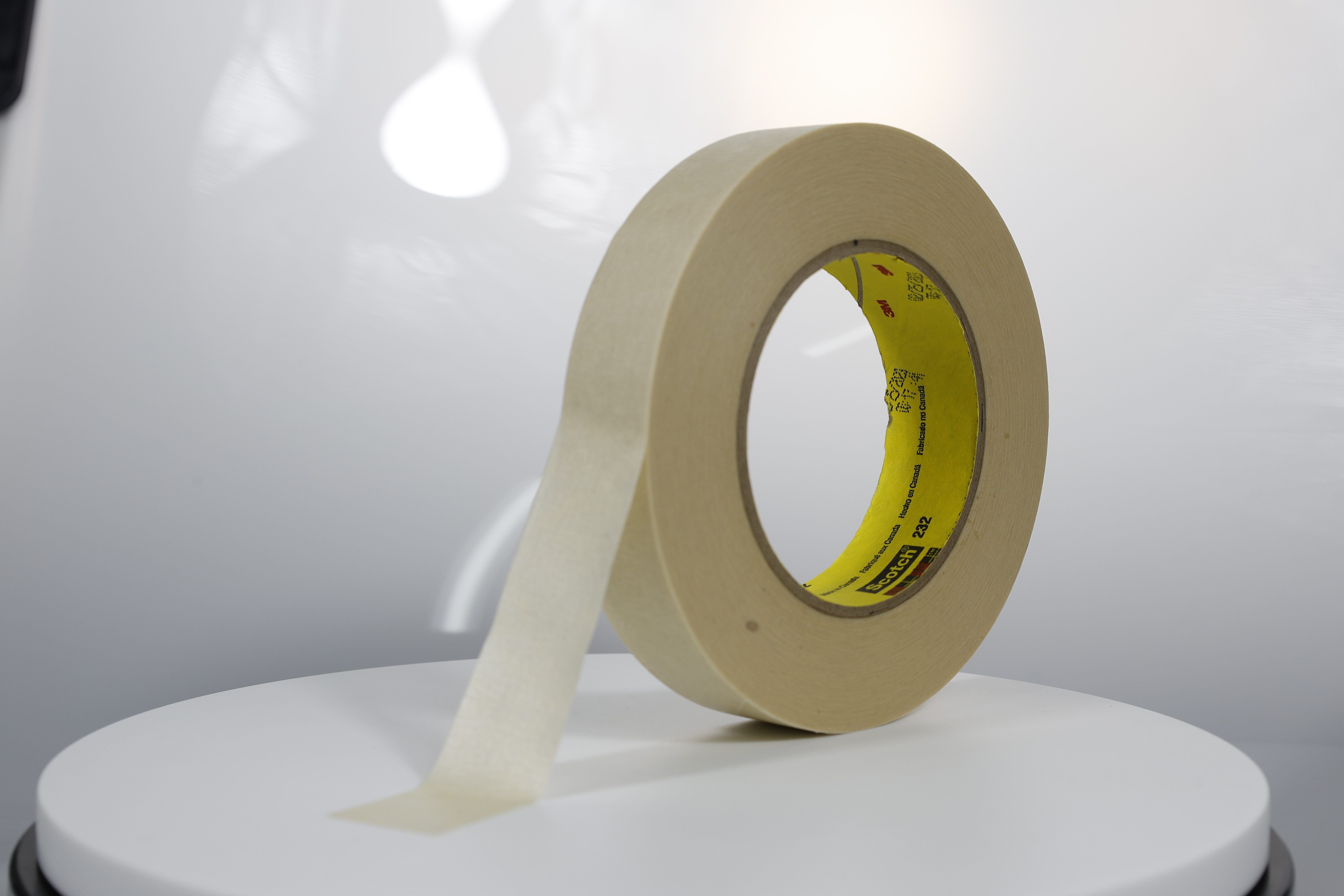

Understanding the different types of electrical tapes and their uses is essential. Masking tape is primarily used for painting and labeling due to its easy removal and lack of residue. Painter's tape, a variant of masking tape, offers better adherence to surfaces and is used in painting to achieve clean lines. Rubber tape is notable for its elasticity and is used for high voltage insulation tasks because of its water resistance and adherence to itself. Insulating tape, typically made from vinyl, is versatile for general electrical insulation, providing abrasion resistance and moisture protection. Double-sided tape, though not traditionally used for electrical purposes, can secure components within electrical panels temporarily.

In electrical applications, each tape type brings unique advantages. Rubber tape is invaluable for areas requiring moisture resistance, while insulating tape is perfect for regular electrical insulation. Using them alongside UV-resistant tapes enhances durability in outdoor or harsh conditions, ensuring long-lasting electrical safety and efficiency. These tapes complement each other, amplifying their collective strengths in various scenarios.

Tips for Properly Using UV-Resistant Electrical Tape

To ensure optimal performance of UV-resistant electrical tape, begin by preparing the surface thoroughly. Clean and dry the area to enhance adhesion, as applying on wet surfaces can compromise effectiveness. When applying the tape, maintain consistent tension to prevent wrinkles or air pockets, which can weaken the seal. Aim for a thickness that adequately covers the area without overstretching the tape. This balance is crucial for durability and effectiveness. Avoiding common pitfalls is essential. Do not use the tape on wet surfaces as it may not adhere properly. Additionally, ensure the tape fully adheres to the edges to prevent peeling. Finally, refrain from applying it in extreme temperatures to maintain its adhesive integrity and UV resistance. By keeping these guidelines in mind, you can maximize the effectiveness and longevity of your UV-resistant electrical tape applications.

Recommended Products

Hot News

Hot News

-

Pakistan Business Delegation Visits Our Factory, Seals Partnership With Immediate Deposit

2025-04-29

-

TAPE Team Conquers Shenzhen’s Phoenix Mountain: Unity, Ambition, And New Heights In 2025

2025-02-21

-

The Role of Polyimide Electrical Tape in Electronics Insulation

2025-01-21

-

High Strength Double-sided Tape for Secure Bonding

2025-01-15

-

Durable Foam Tape for High-Performance Applications

2025-01-10

-

High Temperature Resistant Masking Protective Tape for Extreme Conditions

2025-01-01