What Makes Double Coated Tape Ideal for Electronics Assembly

Core Properties and Functions of Double Coated Tape in Electronics

Precision Bonding Through Consistent Adhesive Layer Control

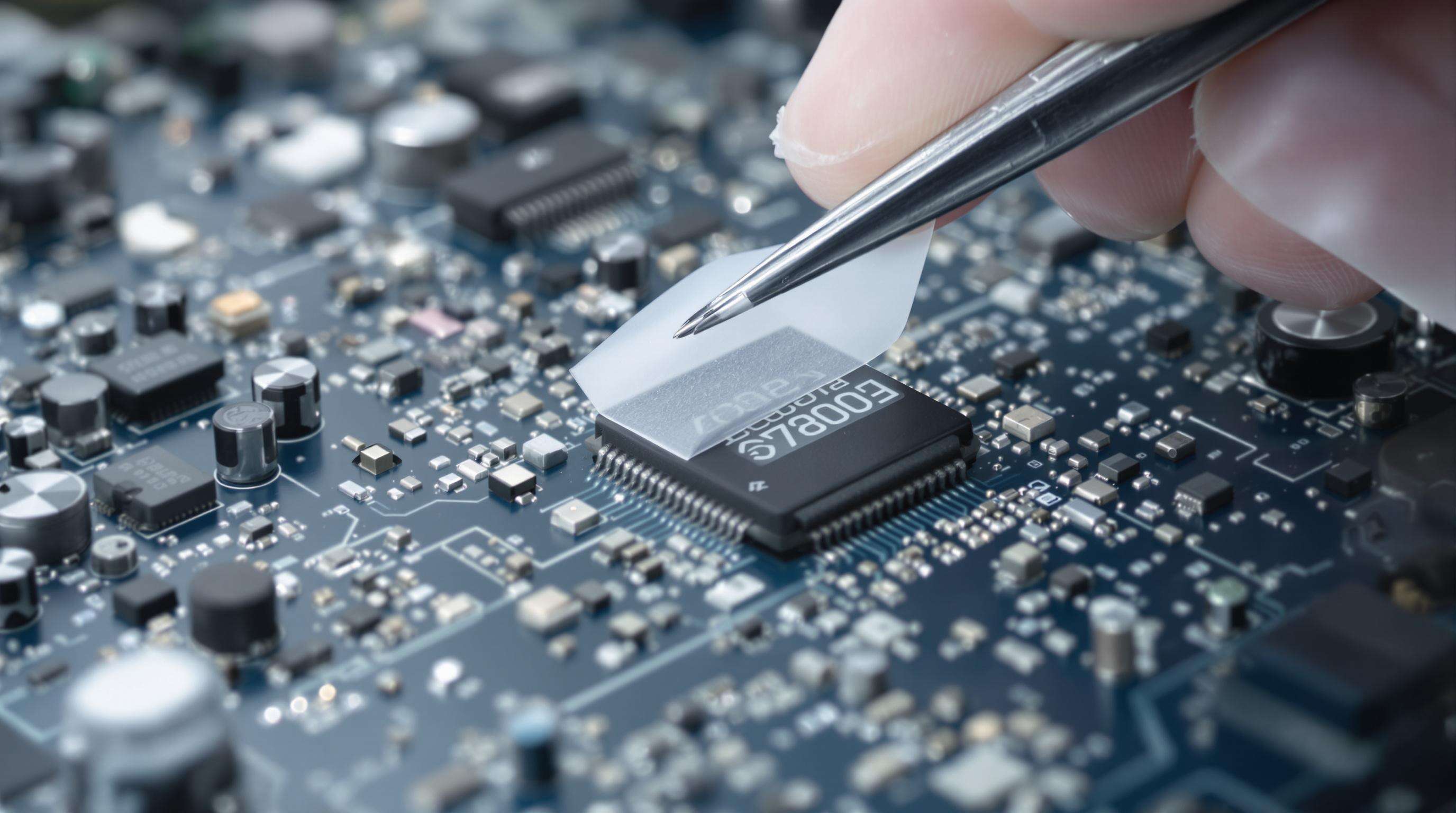

Double coated tapes deliver exceptional precision at the micron level during electronic component assembly thanks to sophisticated adhesive layer designs. The uniform thickness control, typically within plus or minus 5 microns, makes these tapes ideal for bonding delicate parts such as microprocessors and MEMS sensors without worrying about messy adhesive overflows that plague traditional liquid glues. When it comes time to select the right tape, manufacturers tweak factors like viscosity and stickiness depending on what they're attaching to. Most shops have noticed a trend toward acrylic-based formulas lately. Market data indicates around two thirds of industrial tapes being used today fall into this category because they hold up better under heat and physical stress compared to other options.

Key Properties Enabling Reliability in High-Density and Miniaturized Circuits

Modern tapes combine three critical properties for circuit reliability:

- Dielectric strength (15–25 kV/mm) to prevent micro-arcing

- Dimensional stability (<0.1% shrinkage at 150°C)

- Creep resistance under constant vibration (per MIL-STD-810H)

These characteristics are essential in 5G mmWave devices, where 0.2 mm pitch components require permanent, space-efficient bonding solutions.

Comparison With Mechanical Fasteners and Liquid Adhesives

Unlike screws that concentrate stress or liquid adhesives requiring curing, double coated tape provides instant bonding with uniform load distribution. A 2023 assembly line comparison demonstrated its advantages:

| Parameter | Mechanical Fasteners | Liquid Adhesives | Double Coated Tape |

|---|---|---|---|

| Installation Time | 45 sec | 90 sec (+curing) | 8 sec |

| Failure Rate | 12% | 9% | 2.3% |

| Z-Height Added | 1.2 mm | 0.3 mm | 0.05 mm |

Thermal and Electrical Insulation Capabilities of High-Performance Adhesive Tapes

Advanced silicone-based formulations offer thermal conductivity up to 3.5 W/mK while maintaining 10¹–Ω·cm volume resistivity. This dual functionality allows tapes to replace traditional TIMs (Thermal Interface Materials) and insulating pads in compact IoT devices, reducing bill-of-materials costs by 18% in consumer electronics.

Critical Applications in Modern Electronic Devices

Mounting components in smartphones and wearables using thin double coated tapes

Double coated tapes that are really thin work great for attaching batteries and microphones inside gadgets that need to be less than 8mm thick overall. These tapes have super thin adhesive layers at just 0.05mm thick but still hold up when things get shaken around a lot. That matters a lot for wearable tech since people bend their wrists thousands of times every day. The latest numbers from the Electronics Assembly Journal show something interesting happening in our pockets right now. Nearly all smartwatches (like 96 out of 100) and most smartphones (about 82%) actually use these sticky tapes rather than traditional screws these days. This switch saves valuable space inside the device - manufacturers report between 15% to 30% more room available - plus it keeps components from moving around which can cause problems down the line.

Bonding displays, sensors, and camera modules with precision tape solutions

Double coated tapes now reach alignment tolerances as tight as plus or minus 0.1mm when used with OLED displays and those complicated multi-lens camera setups we see these days. The secret lies in proprietary acrylic adhesives that spread out shear stress over whole surfaces rather than concentrating it in one spot. This actually cuts down on image sensor calibration problems by around 40% when lighting is poor, which makes a big difference in night time photography. Some research from last year showed something pretty impressive too: components bonded with tape lasted through about 50% more temperature swings from -20 degrees Celsius all the way up to 85 degrees compared to parts mounted with solder in modern 5G phones. That kind of durability really matters in devices that go through extreme environments.

Use in semiconductor packaging and flexible printed electronics

In wafer-level chip-scale packaging, antistatic double coated tapes secure die-attach processes with less than 3µm positional drift during thermal compression bonding. Flexible hybrid electronics manufacturers use urethane-based tapes that withstand 300°C reflow temperatures while maintaining 12 N/cm² adhesion to polyimide substrates—outperforming epoxy alternatives by 60% in bend-test simulations.

Role of Double Coated Tape in Reducing Device Thickness and Weight

Modern electronics demand sub-2mm profiles unattainable with traditional fasteners. Double coated tapes eliminate screws and clips while delivering 8–12 N/cm² shear strength (IEEE Components & Packaging Society, 2023), enabling 23% thinner smartphone designs. This adhesive approach removes height variations from mounting hardware, ensuring consistent skin contact in medical wearables.

Achieving Ultra-Slim Profiles With Sub-50-Micron Conductive and Heat-Resistant Tapes

The latest generation of acrylic adhesives brings together impressive thermal properties with remarkable thinness. They offer around 0.03 W per meter Kelvin conductivity and measure just 50 micrometers thick overall, making them about seventy percent thinner compared to traditional epoxy options. These materials can handle multiple reflow cycles at temperatures reaching 150 degrees Celsius without peeling away from surfaces. At the same time, they keep components separated by less than half a millimeter electrically isolated from each other. This kind of exactness is really important for foldable display technology. The alignment needs are incredibly tight, sometimes as small as 0.1 mm differences, and getting this right makes all the difference when it comes to how long those hinges will last before wearing out.

Case Study: Adhesive Tape in Foldable Phone Hinge Assemblies

A 2023 teardown analysis revealed a 35-layer adhesive system in foldable devices, with double coated tapes providing:

| Function | Performance Metric |

|---|---|

| Hinge Flex Life | 200,000+ cycles maintained |

| EMI Shielding | 60 dB attenuation at 6 GHz |

| Thermal Cycling | -40°C to 85°C stability |

This multi-functional bonding approach reduces hinge complexity by 40% compared to early prototypes that used micro-screws and solder joints.

Advantages Over Traditional Assembly Methods

Superior stress distribution and vibration resistance in compact devices

Double coated tapes eliminate stress concentration points inherent in mechanical fasteners. A 2023 materials science study demonstrated that adhesive-bonded joints reduce peak stress by 40–60% in smartphone PCB assemblies compared to fastened joints. This even distribution prevents solder joint fractures during drops while maintaining sub-0.1 mm bondline thickness for space-constrained designs.

Elimination of drilling, welding, and curing steps with double coated tape

Modern double coated tapes work under pressure to create bonds instantly without needing heat or solvents. Factories can cut out around five steps in their process these days drilling holes, getting surfaces ready, putting in fasteners, checking welds, and waiting for adhesives to cure. According to the Consumer Electronics Manufacturing Report from 2024, this change alone cuts down on camera module assembly time by about three quarters. Plus it stops those tiny cracks that often form when things get welded with heat, which is a real problem in precision electronics manufacturing.

Enhanced durability under thermal cycling and mechanical stress

High-performance acrylic foam cores maintain adhesion integrity across -40°C to 150°C, outperforming epoxies that become brittle below -20°C. Accelerated aging tests show less than 5% adhesion loss after 5,000 thermal cycles in automotive sensor installations, compared to 25–40% degradation in silicone-based liquid adhesives under the same conditions.

Innovations in Adhesive Materials for Next-Gen Electronics

Technological Advancements in Tapes for 5G, IoT, and High-Frequency Devices

The latest generation of electronic gadgets needs special adhesives designed to handle those super high frequency signals while also sticking tiny components together properly. Right now, companies are working on these fancy double sided tapes that keep their electrical characteristics consistent even when frequencies go past 30 GHz, which matters a lot for things like 5G antenna systems and those millimeter wave communication devices we hear so much about. What makes these tapes work so well is how they mix in microscopic conductive particles with really thin pressure sensitive layers, sometimes as little as 25 microns thick. This allows manufacturers to put RF shielding exactly where it needs to be inside those small Internet of Things sensors without taking up extra space.

Development of Thermally Conductive and EMI-Shielding Adhesive Tapes

Material science labs across the globe are developing these new generation adhesives that handle both heat management and electromagnetic interference at once. Recent research from last year showed something pretty interesting - those special thermal tapes rated at least 5 W/mK actually cut down smartphone processor temperatures by around 18 degrees Celsius. At the same time, manufacturers are starting to swap out traditional metal gaskets for these advanced EMI shielding tapes infused with carbon nanotubes. They get impressive results too, blocking signals with 60 dB attenuation while being incredibly thin, just 0.1 millimeters thick. The fact that these materials can do two jobs at once makes them absolutely essential for things like foldable phone screens where space is tight, and also critical for automotive radar systems that need reliable performance without overheating issues messing up their signals.

Are Pressure-Sensitive Adhesives Keeping Pace With Evolving Electronics Demands?

While PSA (Pressure-Sensitive Adhesive) tapes excel in miniaturized assemblies, three challenges remain:

- Sustaining peel strength beyond 10,000 thermal cycles (-40°C to 125°C)

- Preventing ionic contamination in semiconductor-grade bonding

- Enabling reworkability for multi-layer PCB repairs

Recent advancements in silicone-acrylic hybrid chemistries show promise, with test units maintaining 95% of initial adhesion after 3,000 humidity cycles. As 6G prototypes emerge, the industry roadmap targets adhesives capable of 200°C stability with sub-micron alignment tolerances.

FAQ

What are the core properties of double coated tape in electronics?

Double coated tape features dielectric strength, dimensional stability, and creep resistance, which ensure reliability in high-density and miniaturized circuits.

Why is double coated tape preferred over mechanical fasteners in electronics?

Double coated tape offers superior stress distribution, vibration resistance, and eliminates steps such as drilling and welding, which enhances durability and reduces assembly time.

How does double coated tape contribute to the miniaturization of electronic devices?

Double coated tape facilitates thinner and lighter device designs by eliminating traditional fasteners, optimizing space, and maintaining structural integrity with high shear strength and precise adhesive layering.

Recommended Products

Hot News

Hot News

-

Pakistan Business Delegation Visits Our Factory, Seals Partnership With Immediate Deposit

2025-04-29

-

TAPE Team Conquers Shenzhen’s Phoenix Mountain: Unity, Ambition, And New Heights In 2025

2025-02-21

-

The Role of Polyimide Electrical Tape in Electronics Insulation

2025-01-21

-

High Strength Double-sided Tape for Secure Bonding

2025-01-15

-

Durable Foam Tape for High-Performance Applications

2025-01-10

-

High Temperature Resistant Masking Protective Tape for Extreme Conditions

2025-01-01