In the automotive industry? High - performance masking tapes are key for a top - notch finish.

Key Features of High-Performance Masking Tapes

Temperature and UV Resistance for Automotive Environments

High-performance masking tapes are engineered to withstand extreme temperatures, making them ideal for demanding automotive paint jobs. These tapes can endure conditions as harsh as 300°F (149°C), which is often required during the car painting process. Additionally, they offer excellent UV resistance, which is essential to prevent degradation and maintain adhesion even when exposed to prolonged sunlight. This makes high-performance masking tapes reliable and ideal for use in environments prone to dynamic temperature changes and high UV exposure.

Premium Conformability on Curves and Contours

High-performance masking tapes are designed with exceptional conformability that makes them perfect for automotive environments. These tapes are engineered to adhere securely to curves and contours, ensuring accurate and precise application on even the most intricate vehicle shapes. This feature is invaluable for achieving sharp paint lines and comprehensive coverage, which significantly enhances the overall quality and aesthetics of automotive paint jobs. Professional mechanics and car enthusiasts will appreciate the precision these tapes provide in giving their vehicles a polished and professional appearance.

Clean Removal Without Adhesive Residue

The ability of high-performance masking tapes to ensure clean removal is essential to preserving the integrity of freshly painted surfaces. These tapes are designed to remove easily without leaving behind any sticky residue, thereby minimizing the risk of marring the underlying finish. This clean removal translates to reduced time spent on additional clean-up and prevents any unnecessary damage to the finished paint job. Therefore, high-performance masking tapes are indispensable for technicians who value maintaining the pristine quality of vehicle surfaces post-painting.

Superior Paint Line Precision and Edge Retention

Achieving sharp paint lines and maintaining their integrity is vital in automotive refinishing, and high-performance masking tapes excel in this area. These tapes are engineered to create clearly defined edges and prevent paint from bleeding, which are crucial for producing high-quality paint finishes. By ensuring that lines remain precise even during the painting process, high-performance masking tapes contribute significantly to maintaining edge retention. This makes them a go-to option for professionals aiming to achieve a seamless and professional-grade finish on vehicles.

For those seeking reliability and efficiency, exploring the various Rust-Oleum® Automotive Masking Tapes can lead to the right choice for any need.

Top Automotive Masking Tape Recommendations

Performance Green Masking Tape 233+ for Professional Use

The Performance Green Masking Tape 233+ is a standout choice for professionals in the automotive field due to its exceptional adhesion and temperature resistance. This tape is perfect for both indoor and outdoor applications, ensuring consistent performance even under challenging conditions. Its unique composition allows for clean removal without leaving any adhesive residue, a critical feature for high-quality, flawless paint jobs. For more detailed insights and to explore this product further, visit the Performance Green Masking Tape 233+.

3M™ High Performance Green Masking Tape 401+ for Heat Resistance

Specifically formulated for high-heat applications, the 3M™ High Performance Green Masking Tape 401+ is indispensable in the automotive industry, where temperature resistance is crucial. This tape not only withstands high heat but also offers superior UV resistance, thereby minimizing the risk of adhesive failure under prolonged exposure to sunlight. These features make it an ideal and reliable option for those dealing with elevated temperatures during painting. You can learn more about this tape through the 3M™ High Performance Green Masking Tape 401+.

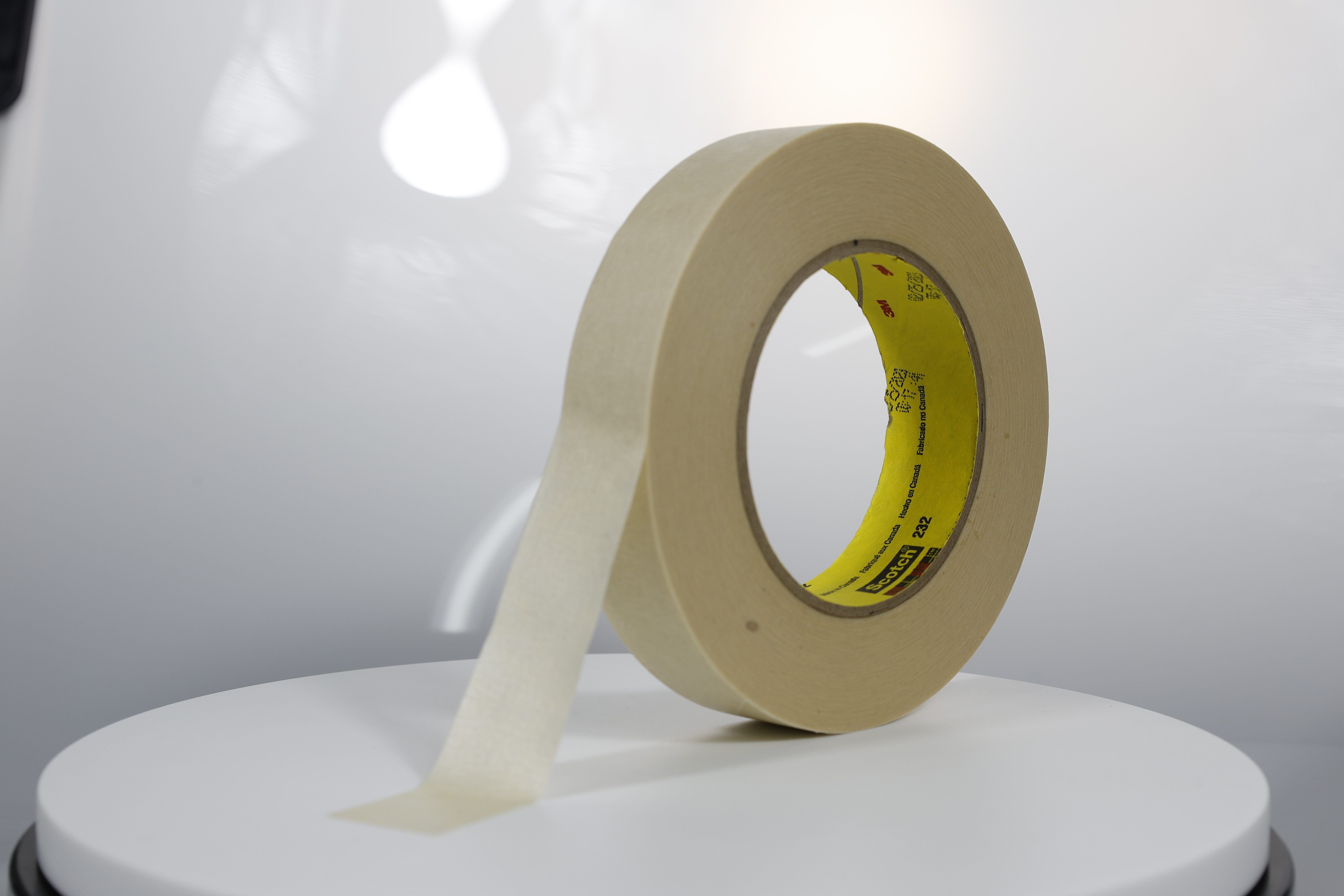

3M™ Paper Masking Tape 2214 for Cost-Effective Indoor Projects

For those seeking an economic choice for indoor projects, the 3M™ Paper Masking Tape 2214 is an excellent option. This tape offers reliable adhesion without the excess stickiness often found in premium tapes, making it perfect for light-duty applications. It is notably cost-effective, yet it provides the essential features necessary for precision in indoor tasks, such as clean removal to protect underlying surfaces. More details about this product can be accessed via 3M™ Paper Masking Tape 2214.

Application Techniques for Flawless Paint Results

Surface Preparation Best Practices

Proper surface preparation forms the cornerstone of impeccable paint results. This involves cleaning and sanding the surface to eliminate contaminants, ensuring the tape adheres effectively without interference from dust or grease. Using a primer before applying paint can significantly improve adhesion and longevity, providing a more durable finish. By adopting these best practices, you can increase the chances of achieving a perfect paint job, eliminating unnecessary rework and maintaining a professional appearance.

Masking Complex Automotive Geometry

When working with vehicles that have complex shapes, masking can become challenging. To ensure flawless coverage without paint seepage, cut strips of tape to fit snugly into grooves and seams. Flexible tapes, such as rubber or insulating tapes, are ideal for navigating curves, offering the necessary adaptability to cover the intricate contours of automobile surfaces. This meticulous approach helps achieve seamless masking, resulting in clean and finished paint lines around complex geometries.

Timing for Optimal Tape Removal

Timing is crucial when it comes to removing masking tape to prevent peeling or damaging the paint finish. Generally, it is recommended to remove the tape when the paint is slightly tacky, as this ensures sharp, clean lines without lifting the fresh paint layer. This practice not only maintains the integrity of the newly applied paint but also reduces the risk of damage, ensuring optimal results every time. Implementing the correct timing for tape removal is an essential technique in achieving professional-grade refinishing.

If you're interested in learning more about the application techniques for various types of tape, particularly double-sided tape, explore our related posts on double-sided tape applications.

Why Automotive-Grade Tapes Outperform Regular Options

Comparison of Adhesive Strength and Durability

Automotive-grade tapes offer superior adhesive strength compared to regular options, ensuring they stay securely in place during the painting process. This enhanced adhesion means these tapes are less likely to peel off, even when subjected to the adherent forces of a paint spray booth. Furthermore, the durability of these tapes is unmatched; they are designed to withstand harsh automotive environments, including exposure to high temperatures and moisture, where regular masking tapes might disintegrate or lose effectiveness.

Resistance to Automotive Fluids and Solvents

The resistance of automotive-grade tapes to common automotive fluids and solvents is invaluable, especially in a paint shop environment. These tapes maintain their adhesive qualities even when exposed to various chemicals that are part and parcel of automotive painting processes. This characteristic is critical because it ensures the tapes do not degrade, preventing unwanted seepage under the tape that could ruin paint jobs and increase labor costs.

Specialized Backings vs. General-Purpose Paper

Automotive-grade tapes boast specialized backings that enhance their flexibility and puncture resistance, offering an edge over standard paper-backed masking tapes. These backings are engineered to accommodate the complex shapes and angles encountered in vehicle bodies, allowing for a seamless application without tearing. This advantage becomes particularly noticeable on more intricate work that requires precision masking, ensuring that the application yields a flawless finish every time.

Choosing the Right Tape for Your Project

Matching Tape Properties to Paint Systems

Selecting the right tape for your project begins with aligning the tape's properties to the paint system you intend to use. It's crucial to consider factors such as adhesion level and temperature rating to ensure that the tape will hold up during the entire painting process. By understanding these properties in context with your paint system, you'll enhance the performance of masking tapes, leading to a superior finish and minimizing the risk of adhesive failure or paint bleeding.

Evaluating Surface Materials and Job Duration

Equally important in choosing the right tape is evaluating the surface materials and the job duration. Different surfaces require different specifications for optimal adhesion; what works well on metal might not be ideal for plastics. Additionally, if your project is long-term, you'll want a tape with greater durability to maintain its effectiveness over an extended period. This consideration is essential to preventing issues such as tape lifting or adhesive residue left behind once the job is complete.

Budget vs. Performance Tradeoffs

Often, there’s a temptation to opt for budget-friendly tapes, but a careful assessment of budget against performance is necessary. Investing in high-performance masking tape may initially seem more costly, but it significantly reduces the risk of expensive mistakes like flawed paint edges or adhesive residue cleanup. Thus, weighing the benefits of performance against cost ensures that you make informed decisions that won’t compromise the quality of your work.

Recommended Products

Hot News

Hot News

-

Pakistan Business Delegation Visits Our Factory, Seals Partnership With Immediate Deposit

2025-04-29

-

TAPE Team Conquers Shenzhen’s Phoenix Mountain: Unity, Ambition, And New Heights In 2025

2025-02-21

-

The Role of Polyimide Electrical Tape in Electronics Insulation

2025-01-21

-

High Strength Double-sided Tape for Secure Bonding

2025-01-15

-

Durable Foam Tape for High-Performance Applications

2025-01-10

-

High Temperature Resistant Masking Protective Tape for Extreme Conditions

2025-01-01